Polyester panels HP panel

• Used to install cold stores and air-conditioned buildings designed to produce, pack, store and distribute foodstuffs.

• Behaviour in fire B-s3, d0.

• Tongue and groove assembly.

• Recessed sealant to make joints airtight and watertight.

• Invisible fixings.

Atmospheric conditions-Ambient conditions

The laminate polyester coating is designed to stand up to the most aggressive Ai6 atmospheres.

Main characteristics

Insulating core

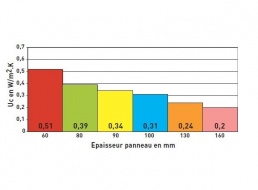

- Injected polyurethane foam, average density 40 kg/cu. m.

- Compressive strength (or distortion stress of 10%).

- Minimal value: 0.10 MPa.

- Reinforced insulation: λ = 0.032 W/m.K.

Facings

- Interior and/or exterior facing made of: Laminated polyester thickness 1.5 mm with food grade gel coat.

- Facing mechanically anchored in the polyurethane foam.

- Standard colour: white 9010.

- Other colours: contact us.

- Adhesive protective film, 35 μ thick.

- Option: Laminated polyester 2 mm thick with food grade gel coat.

Machining for welded joints.

Other facing:

- Z 275 galvanised steel sheet, bare, 0.6 mm thick.

- Z 225 galvanised steel sheet, coated, 0.6 mm thick.

- Polyester lacquer finish, 25 μ thick, as standard.

- Colours: white RAL 9010, sand 42. Other colours: on demand, see RAL colour chart.

- Other possible coatings: PVDF 35 μ, PVC 120 μ, Pet 55 μ (indoors only)

- Protective film: transparent heat-sealing adhesive, 80 to 120 μ thick (except Pet: adhesive film 35 μ thick)

• Option: sheet steel 0.75 mm thick.

- 304 or 316 stainless steel sheet, coated or not, 0.6 mm thick, PVDF lacquer finish,

35 μ thick.

- Opaque protective film

Available dimensions

Module: 1,200 mm.

Max. length: 12 m.

Thickness: 60 - 90 - 130 - 160.